Iot and wire ropes

(Reading time: 2 min)

Internet of things has experienced a period of great development in recent years, covering countless applications. Today it is possible to monitor many different variables on a machine and view them on your PC or smartphone.

Although it is possible to monitor almost everything, applications involving the control of wire ropes are not a standard in industry.

Ropes and tiny ropes can have a crucial role in the daily working routine. They usually lift something more valuable than their pure cost. Their strategic importance is expressed in production line, where a stop due to a broken wire can cost hundreds of thousands of euro per hour. These ropes need to be monitored 24/7. In this article, we will explain the importance of the predictive analysis and the threshold alarm through a permanent installation.

Picture 1.- Example of permanent installation on Overhead Crane

THE PERMANENT SYSTEM

This solution is constituted by an MRT sensor placed on the crane, that can continuously monitor the rope condition, and an intelligent unit calculating a descriptive parameter about the rope status. This parameter will be sent through the network (ex. WiFi) to a data center that can be in the same location or not, and the maintenance team is alerted when an inspection is needed. At the same time, when the standard control is performed, the technician knows in advance the condition of the rope and can optimize its job.

1. GAUGE & TRHESHOLD ALARM

The inspection data are sent to the inspection center on a daily basis, in the form of an app or an HTML page.

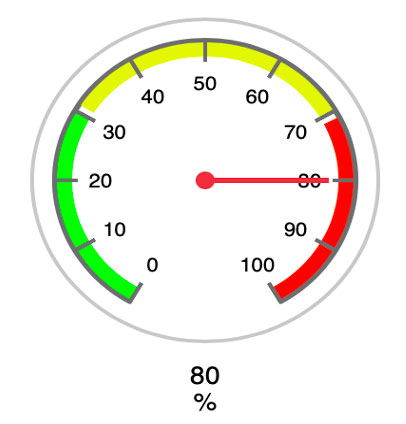

The technicians access this page and look at the status of the rope through a gauge (Picture 3.)

Each coloured area represents a defined status of the rope:

- Green: the rope is in good condition

- Yellow: ask the technicians for a deeper inspection

- Red: Stop the plant, (proceed only under the guidance of a technician)

Each time the rope crosses an area, an alert can be sent to maintenance through message, email etc.

Picture 2. Wire rope deterioration Gauge

PREDICITVE ANALYSIS

A constant control guarantees daily rope status data, which allows the technician to build a predictive analysis.

Picture 3.- Wire rope deterioration graph

The rope status can be evaluated day by day, building the related graph (Picture 3.) The horizontal axe of the following graph is time while the vertical is volt. Each point represents a specific status of the rope, the more the rope is deteriorated, the steeper the curve. Through the analysis of the defects evolution the inspector will know the right time to replace a rope, managing its full life cycle.