Is your mrt device in compliance with the en12927?

(Reading time: 4 min)

The regulation defines how to perform measurements, how to take a technical decision and how to develop a safe and correct process. Regulations must be followed for different reasons.

Firstly, they are written by worldwide acknowledged experts that know perfectly the right processes. The procedure for creating or modifying a standard is extremely long, it can last years. Different phases must be followed to ensure that everything has been set correctly.

Furthermore, in case of troubles, providing an inspection report in compliance with the regulation will legally protect the technicians.

In this article we will analyse EN12927, a well-known regulation covering safety requirements for cableway installations designed to carry people. We will focus on Chapter 14 of the new version which corresponds approximately to part 8 of the old version.

INTRODUCTION

Chapter 14 of EN12927 defines the characteristics of a Magnetic Rope Test (MRT) device, especially for what concerns inner defects sensitivity. This part of the standard is reported in the new ISO4309:2017 for defining the mandatory characteristics of an MRT equipment.

Is it objectively possible to know the sensitivity of a device? How?

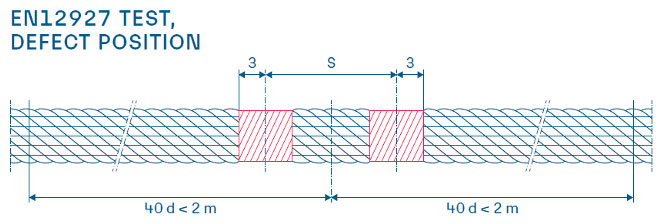

Picture 1.- EN12927 test, defect position

In the cableway sector every MRT devices must be certified by the EN12927 test. This certification states the minimum sensitivity level the equipment must have.

Picture 1. shows the EN12927 sensitivity test. The two red points correspond to two inner broken wires. The distance between them is S, whilst 3 represents the gap in mm between the defects. Two broken wires, artificially made in the inner wire (king wire) of the rope, represent the most difficult situation to be detected.

Picture 2.- EN12927 test, king wire

This test is usually performed on locked coil wire ropes. The LATIF of Trento is one of the most important institution in the world for this special test.

THE TEST

The section loss caused by the defects is lower than 0.5% and the distance from the device is maximum at the rope centre.

For this reason, EN12927 is a strong proof of the sensitivity of a device. The equipment must completely saturate the rope and it must report a well-defined signal, with a signal/noise > 2

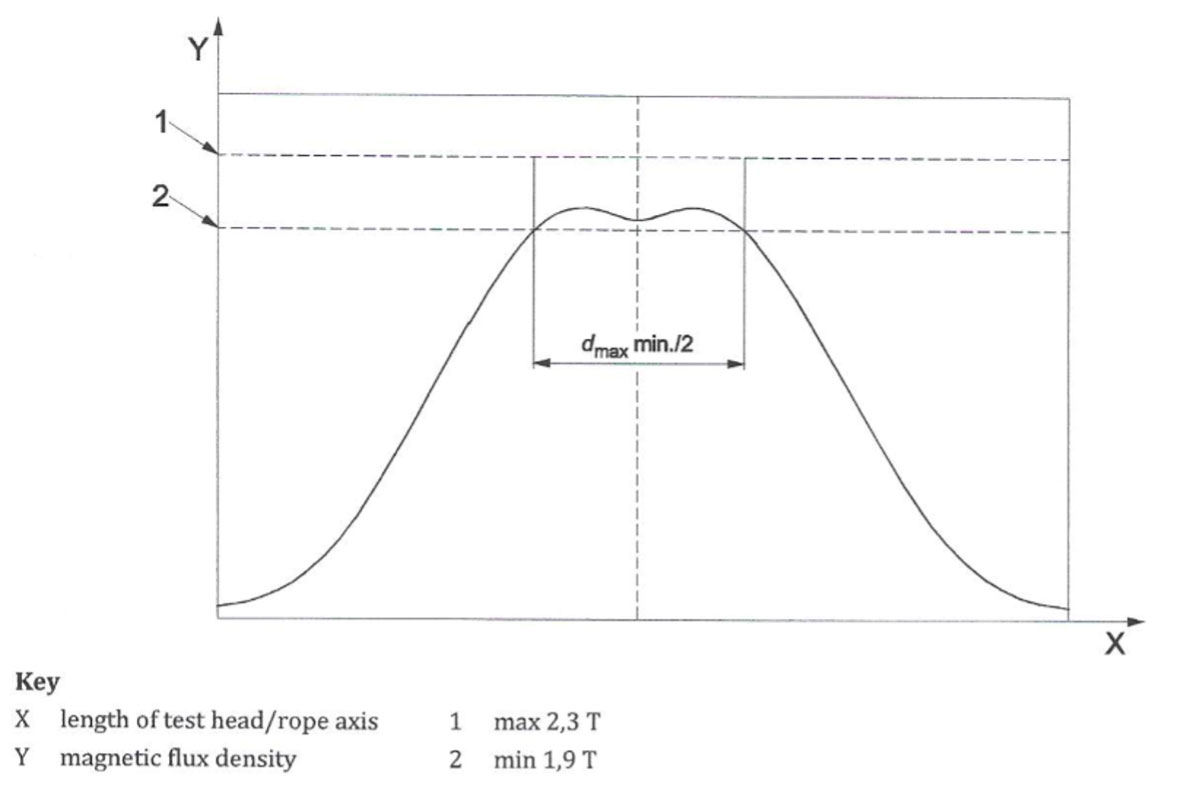

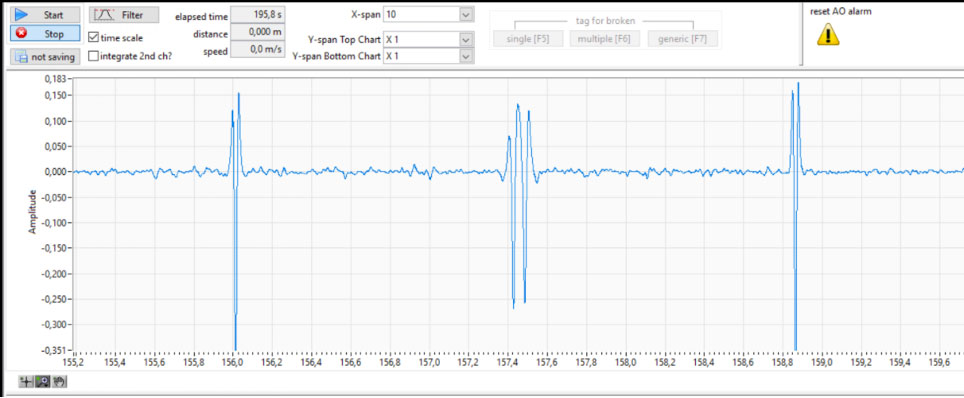

Picture 3.- EN12927 test, diagram

The two big signals at the beginning and at the end of the diagram are artificial defects used to define the test length on the rope. The two peaks in the middle are two internal defects. Following the regulation, if the zero to peak amplitude of the signal is at least the double of the noise level (peak to peak) the test is successful. Otherwise the device cannot be used in the cableway’s environment.

Why is this test so important?

This is the only test that allows us to understand if an MRT system can find internal damages on a rope. This test is not only a 'need for regulation' issue, it is an objective proof that the device you are buying can identify broken wires.

The new EN12927 also sets new limits for the magnetic field forced inside a rope. The magnetic induction inside a rope should be between 1.9T and 2.3T (picture 4). In this way the complete saturation is ensured, and inner defects could be identified.

What happen if your device is not certified under the EN12927 regulation?

There is a high possibility that your system cannot recognize internal problems, such as broken wires and corrosion, especially if your rope is larger than 20mm.

There is also the possibility that external defects are correctly recognized with a high signal to noise ratio, due to the very low noise of the diagram.

In conclusion, always ask to the device supplier a copy of the certification, that can prove the capabilities of the system.