Rope inspection, safety and the iso4309 regulation

(Reading time: 3 min)

In this article, the reader will find all the information for a conscious use of the MRT equipment, perfectly in compliance with the ISO4309 regulation. We hope that this short read will help the rope technicians to evaluate autonomously how to behave during an inspection. This article has been written with the intent of clarifying misinterpretations of the ISO4309 but it cannot substitute in any case the regulation. Each rope technician is highly invited to read ISO4309 before performing any rope inspection.

HOW WAS THE MAGNETO-INDUCTIVE METHOD INTRODUCED IN ISO 4309?

The magneto-inductive method was born at the beginning of the 20th century in the ropeways sector, where safety criteria have always been the strictest. In the following years the technology evolved, devices became smaller, lighter and cheaper and around the 80’s they arouse the interest of the heavy lifting sector. Since the early 2000s, the methodology began to be used widely, especially in the offshore sector, where ropes operate in a very harsh environment.

The usefulness of the method is so relevant that in the ISO 4309: 2010 it was indicated as a valid aid to visual inspection (chapter 5.6), but at the end of 2017 the new version of the standard (ISO 4309: 2017) was finally released, introducing the magneto-inductive test in the assessment methods table for rope status evaluation. New discard criteria were specially defined. The magneto-inductive method officially became an aid to the visual inspections and the preferred solution for performing internal rope inspections.

WHY IS THE MAGNETO-INDUCTIVE METHOD SO IMPORTANT FOR WIRE ROPES INSPECTIONS?

Since the MI method was introduced in ISO 4309 it is a valid aid for the operator for avoiding subjective evaluations (e.g. see ISO4309, Table 3, 4, 5, 6)

The MI method must always be associated with a visual inspection. The competent person detects visible defects and fill out a correct report; if defects are not visible but highlighted by the MRT, the operator rates the severity of the deterioration, as defined by the regulation.

The MRT is often the only way to carry out an internal inspection.

ARE INSPECTIONS DEFINED BY THE REGULATION?

Yes, if the rope manufacturer follows EN12385 - Steel wire ropes – Safety the inspector must always be in compliance with the regulation ISO 4309.

The regulation establishes general principles for care, maintenance, inspection and discard of steel wire ropes operating on cranes and hoists.

ISO4309 states the assessment method for any type of defect that can occur on a rope.

It provides realistic discard criteria and gives a method for evaluating the combined effect of deterioration at any position in the rope.

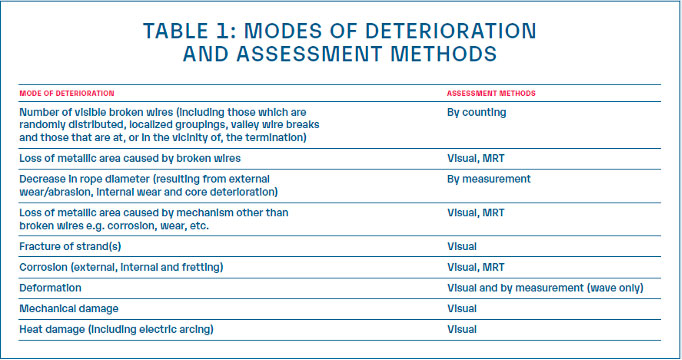

Table 1 of the standard lists the more common modes of deterioration and whether each can be readily quantified or needs to be subjectively assessed by the competent person.

For all these modes of deterioration the competent person must express a severity rating, which is the result of the relative assessment method. For example, regarding the reduction in diameter the measurement is necessary, whilst, regarding the number of visible broken wires, counting is the appropriate method.

Inspectors must evaluate wear and corrosion inside and outside the rope. Furthermore, they must evaluate the loss of metallic section caused by internal and external broken wires.

It is well known that some specific defects generate in the inner part of the rope. In this case it is almost impossible to perform a visual inspection. For this reason, ISO4309 assesses the Magnetic Rope Test as the preferred method for “Loss of metallic area caused by broken wires”, “Loss of metallic area caused by mechanism other than broken wires” and for “Corrosion (external, Internal and fretting)”. Thanks to this specific methodology the competent person is able to inspect the modes of deterioration as prescribed by the regulation.

HOW CAN A PERSON KNOW IF A ROPE MANUFACTURER IS FOLLOWING THE EN12385?

In the European Communities ISO4309 is harmonized in EN12385. Every rope commercialized in Europe must follow EN12385, and it should be written on the specific rope “Use & Maintenance Manual”. The compliance with this latter regulation provides a presumption of conformity with the relevant essential requirements of the directive 98/37/EC. For this reason, the rope manufacturers have two options:

- Following the regulation and reporting it on their “Use & Maintenance Manual”, as inspection procedure

- Issuing a rope certificate defining different discard criteria and assessment methods that must fulfil ISO4309 safety requirements

WHAT IF THERE IS NO “USE & MAINTENANCE MANUAL”?

It could happen that the manual is not available. In this case, it is mandatory to follow the related regulation, for example ISO4309 for ropes. In any case, you must follow the laws of the country where you’re performing the inspection.

CONCLUSIONS

The competent person must be aware of how he’s performing the inspection, because he must keep himself and the plant safe, he must always follow the ISO4309 regulation to be in compliance with the correct inspection procedure. To hasten the efficiency of the MRT method, we highly suggest the reader to check our article: “The visual Inspection and the MRT”. For the most interested readers we recommend the articles listed in the bibliography.

BIBLIOGRAPHY

[1] Technical standard ISO 4309:2017 / UNI ISO 4309:2019

[2] Look Inside the Rope: published by LEEA (Lifting Equipment Engineers Association)

https://leeaint.com/au/News-Look-inside-the-rope

[3] Wire Rope Forensics:

http://www.ropetechnology.com/bro_engl/wire_rope_forensics_a4.pdf

[“internal wire breaks”, pag. 27]

[4] V. Cacciatore, A. Canova, A. Vallan and B. Vusini, “Experience and technologies in NDT of ropes”. KEY ENGINEERING MATERIALS, (2007), vol. 347, pp. 627-632.

[5] A. Canova, B. Vusini, “Magnetic analysis of non-destructive testing detectors for ferromagnetic ropes”, COMPEL: The International Journal for Computation and Mathematics in Electrical and Electronic Engineering, Vol. 27 No. 4, 2008, pp. 869-878.

[6] A. Canova, F. Degasperi, F. Ficili, M. Forzan, B. Vusini “Experimental and numerical characterisation of ferromagnetic ropes and non-destructive testing device”, Proc. of OIPEEC Conferebce 18th – 20th March 2009, Stuttgart, Germany, pp. 289-298.

[7] A. Canova, P. Frighi, P. Boschiazzo, B. Vusini, F. Ficili, “Controllo magneto-indutivo delle funi metalliche per ascensori”, Elevatori, marzo-aprile 2009, pp. 66-74.

[8] H.R. Weischedel, (1999), “Electromagnetic Wire Rope Inspection: Signal Generation, Filtering, and Computer-Aided Rope Evaluation”, The Nondestructive Testing of Rope. Krakow, Poland: (O.I.P.E.E.C.) International Organization for the Study of the Endurance of Wire Rope.